In the construction industry, concrete is one of the most critical materials, and its quality directly influences the durability and safety of buildings, roads, and infrastructure. As construction projects become more complex and require higher precision, investing in high-tech concrete mixer plants has become essential for ensuring the best possible concrete quality. This article will explore how advanced technology in concrete mixer plant can enhance concrete quality, and how to consider factors like concrete batching plant price, concrete batching plant cost, and selecting the right concrete batching plant suppliers.

The Role of Concrete Mixer Plants in Concrete Quality

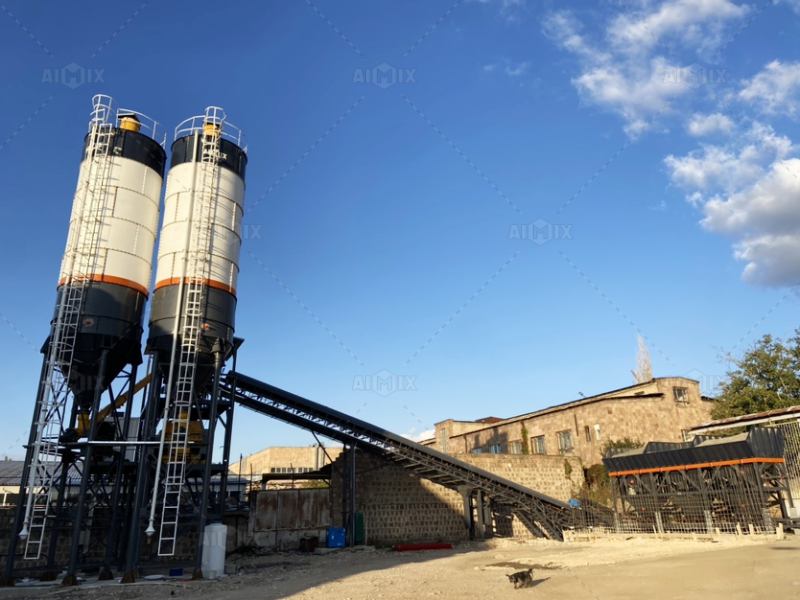

Concrete mixer plants are designed to combine raw materials – cement, sand, aggregates, and water – into a consistent and homogeneous mixture. The accuracy, speed, and consistency of this mixing process are paramount to achieving high-quality concrete that meets the specific strength, durability, and workability requirements of the project. High-tech concrete mixer plants are equipped with advanced technology that helps optimize these factors, ensuring better performance in concrete production.

Key Technologies in High-Tech Concrete Mixer Plants

Advanced Batching Systems

One of the most significant technological advancements in concrete mixer plants is the development of automated batching systems. Modern batching systems control the precise measurement of each ingredient in the mix, ensuring that the proportions of cement, aggregates, and water are consistently accurate. This level of precision is critical in maintaining concrete quality, especially when dealing with complex specifications for different types of concrete.

Batching systems can also adjust in real-time, adapting to slight variations in raw materials or environmental conditions, ensuring that each batch is mixed to perfection. This not only improves the overall quality but also reduces material wastage, contributing to cost savings in the long run.

Integrated Control Systems

High-tech concrete mixer plants often feature integrated control systems, such as computer-aided design (CAD) and centralized control panels. These systems provide real-time monitoring of the plant’s operations, enabling operators to track and adjust parameters such as mixing speed, water-cement ratio, and aggregate gradation. By ensuring accurate control of these variables, these systems prevent errors that can compromise concrete quality.

Moreover, modern concrete mixer plants come equipped with software that can store and recall specific mix designs, allowing for consistency across multiple batches. This eliminates human error in mix design and ensures uniformity, which is especially important in large projects where high concrete production volumes are needed.

Twin-Shaft and Planetary Mixers

The type of mixer used in a concrete mixer plant can also have a significant impact on concrete quality. Twin-shaft mixers and planetary mixers are the go-to choices for high-tech plants due to their ability to handle high volumes of concrete while maintaining uniform mixing quality. Twin-shaft mixers are known for their efficient and rapid mixing action, producing uniform concrete that meets the highest standards. Planetary mixers, on the other hand, are excellent for producing high-performance concrete and can handle a wide range of materials, including high-strength mixes.

Both of these mixers contribute to superior concrete quality by ensuring a more homogeneous mix, which results in concrete with better workability, strength, and durability.

Automated Material Handling Systems

Material handling plays a vital role in ensuring that concrete is mixed properly. High-tech concrete mixer plants use automated systems to transport raw materials such as aggregates, cement, and water from storage to the mixing area. These systems help eliminate human error, improve efficiency, and reduce the time needed to load materials. The automation of material handling also ensures that materials are consistently delivered in the correct proportions, further improving concrete quality.

Environmental Control Systems

Modern concrete mixer plants are equipped with environmental control systems that ensure minimal dust and emissions, which is essential for maintaining a safe and eco-friendly work environment. These systems also help control the moisture content in aggregates, which can significantly affect the quality of the mix. By maintaining consistent moisture levels, the concrete mix can achieve the desired strength and workability.

Cost Considerations for High-Tech Concrete Mixer Plants

While high-tech concrete mixer plants offer significant advantages in terms of concrete quality, they also come with higher costs. Understanding these costs and making informed decisions is key to balancing quality and budget.

Concrete Batching Plant Price

The concrete batching plant price varies depending on its size, capacity, and the technology it incorporates. High-tech plants equipped with advanced batching systems, mixers, and control technologies tend to cost more than traditional plants. However, investing in such plants can be justified by the long-term benefits of improved concrete quality, increased productivity, and reduced material wastage.

When evaluating concrete batching plant price, it’s essential to consider the overall value, including the operational efficiencies and the potential for higher-quality concrete. For larger-scale projects that require consistent concrete quality, the higher upfront cost can be worthwhile in the long run.

Concrete Batching Plant Cost

A high-tech concrete batching plant cost includes more than just the initial purchase price. Factors like energy consumption, maintenance, and labor costs must be considered. Advanced technology often comes with the advantage of automation, which can help reduce labor costs by minimizing the need for manual intervention.

Maintenance costs may also vary depending on the complexity of the technology used in the plant. High-tech plants may require specialized maintenance and spare parts, which could add to the operational cost. However, the superior quality and efficiency of these plants can result in a lower cost per cubic meter of concrete produced, making them cost-effective in the long term.

Choosing Concrete Batching Plant Suppliers

Selecting the right concrete batching plant suppliers is essential when purchasing high-tech plants. Reputable suppliers not only offer high-quality equipment but also provide after-sales services, including installation, training, and maintenance support. A reliable supplier will help ensure that the plant is optimized for maximum performance and quality production.

When looking for concrete batching plant suppliers, it’s important to evaluate their experience in providing high-tech solutions. A good supplier should be able to guide you through the options available, help you select the right technology for your needs, and offer ongoing support to keep your plant running smoothly. Some suppliers also offer warranties and maintenance packages, which can help offset future repair or replacement costs.

Conclusion

High-tech concrete mixer plants are essential for improving the quality of concrete and ensuring consistency in large-scale construction projects. Technologies like advanced batching systems, automated control systems, and efficient mixers significantly enhance the mixing process, leading to better concrete performance and reduced material waste. While these plants come with higher upfront costs, the long-term benefits of improved quality and operational efficiency make them a valuable investment.

When considering a high-tech concrete mixer plant, it’s important to evaluate the concrete batching plant price, overall operating costs, and the suppliers who can offer the best combination of technology, support, and service. By carefully choosing the right equipment and suppliers, you can ensure that your plant delivers high-quality concrete for years to come, enhancing the success of your construction projects.