Have noticed the increased popularity of cement block making machine for sale advertisements online in recent years? Block making machines are also often called burn-free block making machines and they are used to produce concrete bricks. Arguably one of the best things about making concrete bricks with the latest block making machines is that the finished bricks don’t require any steam or fire curing treatments and can be packaged for distribution or used on-site as soon as they are completely dry.

Learn more about environmental benefits

Many people don’t know about all the environmental benefits of today’s modern auto cement brick making machines for sale. The latest designs employ wastewater recycling technology and dust filters to reduce pollution and preserve natural resources. The high-tech filtering systems fitted to the latest models are essential for pollution-free operation. The raw materials used to manufacture cement blocks can be sourced from industrial waste, mining slag, demolition sites, etc. This means the machines are great for recycling waste in local areas.

The main reasons why cement block making machines have become popular with businesses all over the world is because they deliver fast, large returns for a relatively small investment. The demand for concrete bricks is increasing on global basis every year as developing countries begin to invest more in building and infrastructure expansion. People in the developing world can start a profitable brick manufacturing businesses with very limited starting funds and profits have the potential to grow exponentially. Some of the newest block making machines for sale can output over a hundred thousand blocks in 24 hours.

The main reasons why cement block making machines have become popular with businesses all over the world is because they deliver fast, large returns for a relatively small investment. The demand for concrete bricks is increasing on global basis every year as developing countries begin to invest more in building and infrastructure expansion. People in the developing world can start a profitable brick manufacturing businesses with very limited starting funds and profits have the potential to grow exponentially. Some of the newest block making machines for sale can output over a hundred thousand blocks in 24 hours.

Different finished products

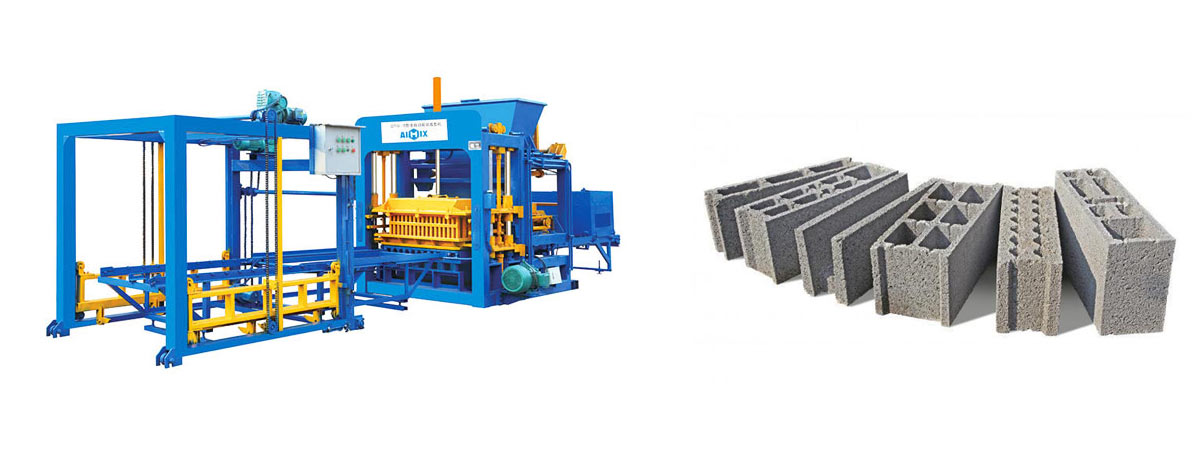

Besides being able to manufacture standard solid concrete blocks (measuring 8″ by 8″ by 16″), block making machines can also produce colored curbstones, porous bricks, interlocking bricks, decorative blocks, paving stones, maple leave bricks, lightweight insulation blocks, hollow bricks, H-shaped pavers and much more. There is a high demand for all different types of blocks for different construction projects around the world. In order to manufacture different styles of blocks, businesses need to invest in additional block molds and change the raw material mixtures. To create colored bricks, for example, dying agents need to be added to raw material mixes.

Get best price

To avail of the best prices on cement block making machines for sale, it’s vital that you obtain quotes from multiple suppliers, including overseas suppliers. The lowest prices are generally available by contacting manufacturers directly or placing an order with overseas vendors, such as those based in China or Pakistan.

Keep in mind that the harga mesin pembuatan batu bata semen is not the only factor that should influence your buying decision. Some of the other parameters to be aware of when comparing different cement block machine models include degrees or automation, hourly block output rate, running costs and more. In terms of automation levels, you can find manual, semi-automatic and fully automatic block making machines in the marketplace. The better the degrees of automation, the more expensive the machine is likely to be. However, you need to keep in mind that fully automatic brick making machines can save your business a small fortune in manual labor costs.